Installation of welded ball valve

Buried all welded ball valves are widely used in various fields. Their superior quality and high-performance stability can not be achieved by ordinary cast steel ball valves. The service life of all welded ball valves is much longer than that of cast steel ball valves. All welded ball valves are widely used in urban gas, urban heat supply, petrochemical industry, shipbuilding, iron and steel, pressure regulating stations, power plants and other pipeline equipment.

1. Pressure test before installation of buried all welded ball valve

Pressure test shall be conducted for pipeline valves before installation to ensure the tightness and safety of the valve itself.

(1) Strength test. The strength test adopts water as the medium; Weld the high-pressure cap on the sleeves on both sides of the valve After opening the valve to 45 ℃, inject water into the ball valve through the pressure test valve on the sleeve Boost the pressure to 1.5 times of the nominal pressure of the ball valve and maintain the pressure for 15min; It is qualified if there is no leakage.

(2) Tightness test. The tightness test adopts nitrogen as the medium; Close the ball valve Inject nitrogen into the ball valve from the pressure test valve on the sleeve The pressure rises to 1.1 times of the nominal pressure of the ball valve, and the middle chamber pressure relief valve is connected with the hose to the water container for testing The insertion depth is 1cm; It is qualified if there is no bubble within 5min.

2. Installation of buried all welded ball valve

(1) Hoisting. The valve shall be hoisted in a correct way. In order to protect the valve stem, do not tie the lifting chain to the handwheel, gearbox or actuator. The protective caps at both ends of the valve sleeve shall not be removed before welding

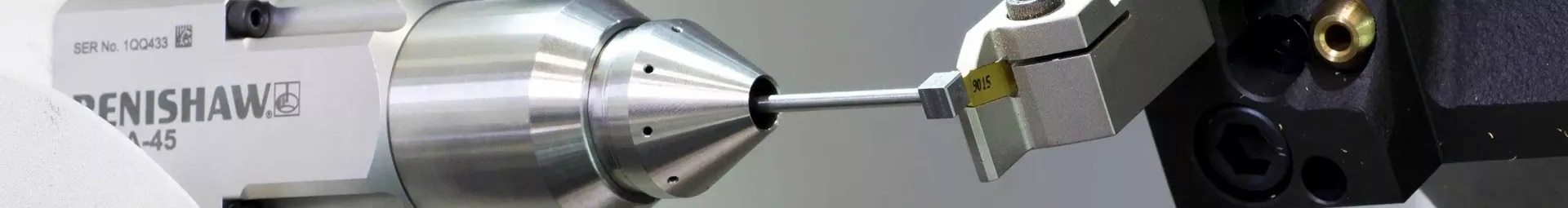

(2) Welding The direct buried all welded ball valve is connected with the main pipeline by welding The weld quality must comply with the grade II film standard of radiographic examination of welded joints of disc fusion welding (gb3323-2005). Generally, one-time welding can not fully guarantee all the qualification. Therefore, when ordering the valve, the manufacturer shall require the manufacturer to add 1.0m long sleeve pipe at both ends of the valve. Once the weld is unqualified, there is enough length to cut off and re weld the unqualified weld. When the ball valve is welded with the pipeline, the valve shall be in the 100% fully open position, In order to prevent the valve ball from being damaged by splashing welding slag, ensure that the temperature of the internal seal of the valve does not exceed 140 ℃, and take appropriate cooling measures if necessary

(3) Masonry of valve well. The directly buried all welded ball valve adopts special

The structural design is maintenance free. Before burying, Pu special anti-corrosion coating is applied on the outside of the valve. At the same time, three injection pipes for emergency grease injection of valve seat and valve rod, the middle cavity vent pipe and valve rod are appropriately extended according to the light ground depth, so that the staff can complete various operations on the ground After the direct burial is realized, the small valve hand well can be built, as shown in Figure 4. For conventional non fully welded ball valves, they can not be directly buried, and large valve wells need to be built. As a result, a dangerous confined space is formed, which is not conducive to safe operation. At the same time, the valve body itself and the bolted connection between the valve body and the pipeline will be corroded, affecting the service life of the valve.

Maintenance of buried welded ball valve

1. Operation of buried all welded ball valve

Frequent operation of the valve can not only prevent the accumulation of impurities on the surface of the valve seat or valve ball, but also avoid local excessive wear of the embedded body in the valve seat

(1) Opening and closing time requirements. Opening and closing the valve too fast will cause the valve to twist and load too much The valve stem is damaged; Switching too slowly will cause the valve seat surface to be washed by the medium for a long time and wear Therefore, the operation time should be kept within an appropriate range According to experience, the lower limit of the control range of valve switching time (seconds) can be half of the nominal size of the valve (inches), and the upper limit can be estimated by 5 times of the nominal size of the valve (inches)

(2) The valve seat shall not be in the fully closed or half open position to avoid damage to the valve seat.

2. Daily maintenance of buried all welded ball valve

The valve seat cavity is the area where the pipeline valve Zui is easy to be polluted In order to ensure the free movement of the valve seat, the well shall be cleaned once a year, and the tightness of the valve shall be checked regularly through the drain nozzle The valves of the auxiliary gas trunk line are often rarely adjusted. They should be opened and closed at Zui least once a year and injected with an appropriate amount of grease to prevent the gluing between the ball and the valve seat and the sub grinding between the ball and the valve seat.

The good technical characteristics of the buried all welded ball valve make the whole gas transmission pipeline integrated (all welded), and enhance the overall stress resistance and geological disaster resistance (such as geological collapse) of the pipeline (including valves) The possibility of air leakage is reduced The reliability of the valve is improved, the service life is prolonged, and the installation and maintenance are also very convenient.