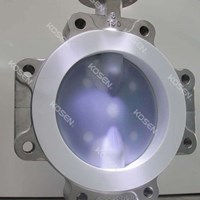

PTFE Lined Butterfly Valve

The KOSEN PTFE Lined Butterfly Valves, not only has the function of cutting off and intercepting flow in the pipeline, but also has taken the sealing performance as the main index for evaluation in recent years, which is favored by the market. In addition, the fluorine lined valve also has the advantages of small volume, light weight and simple structure. Compared with the gate valve with the same parameters, the average weight is reduced by 30-50%. The opening and closing process can be realized by rotating the butterfly plate by 90 °, In addition, the butterfly plates on both sides of the rotating shaft are approximately equal by the medium force and the torque is opposite, so the opening and closing torque is small

Structural features

1. The center line butterfly valve is concentric (center line) between the whole butterfly plate and the valve seat within 360 ° circumference, with two-way sealing function, and the pressure and flow can be adjusted freely;

2. Four stage loading elastic seal absolutely ensures zero leakage inside and outside the valve;

a. The special transition curve at the circumferential connection of shaft head and butterfly plate and the reasonable interference of valve seat;

b. The end face of the shaft head adopts the combination of elastic O-ring, rigid washer at the shaft shoulder and elastic rubber pad;

c. The radial direction of the shaft adopts the combination of O-ring and metal pad;

d. The valve seat is embedded in the valve body groove with elastic strip;

3. The eccentric butterfly valve is two-dimensional. The cam effect caused by eccentricity will make the sealing pair produce enough sealing specific pressure. With the increase of working pressure, the sealing pair will produce enough sealing specific pressure, and the sealing effect is more ideal with the increase of working pressure

4. Flange connected double eccentric butterfly valve shall be used in occasions with high pressure. III. The design specifications shall comply with gb12238, API609, msssp-67 and msssp-68 standards

5. Adjustable marble positioning is adopted, with accurate positioning and simple structure (* O-ring is used to prevent accidental leakage)

Technical Specification

Normal Size Range: 2"-48"

Normal Pressure Rating: PN10~PN16, CLASS150

Material: GG25,GG40,WCB, CF8,CF8M,CF3,CF3M

Operation: Handwheel, Pneumatic, Electric

Temperature Range: -29~150 Degree C

Standards compliance

Design and Manufacture: GB/T12228, API609

Face to face(end to end): GB/T12221

Flanged connection: ANSI B16.5, GB/T 9113

Test and inspection: API 598, GB/T 13927